Usetyenziso

Izinto ezisisiseko kwiipleyiti zedayimani ezihlanganisiweyo zifumana izicelo kwiinkalo ezahlukeneyo ezisekwe kwiipropathi zazo, kubandakanywa kodwa kungaphelelanga apho:

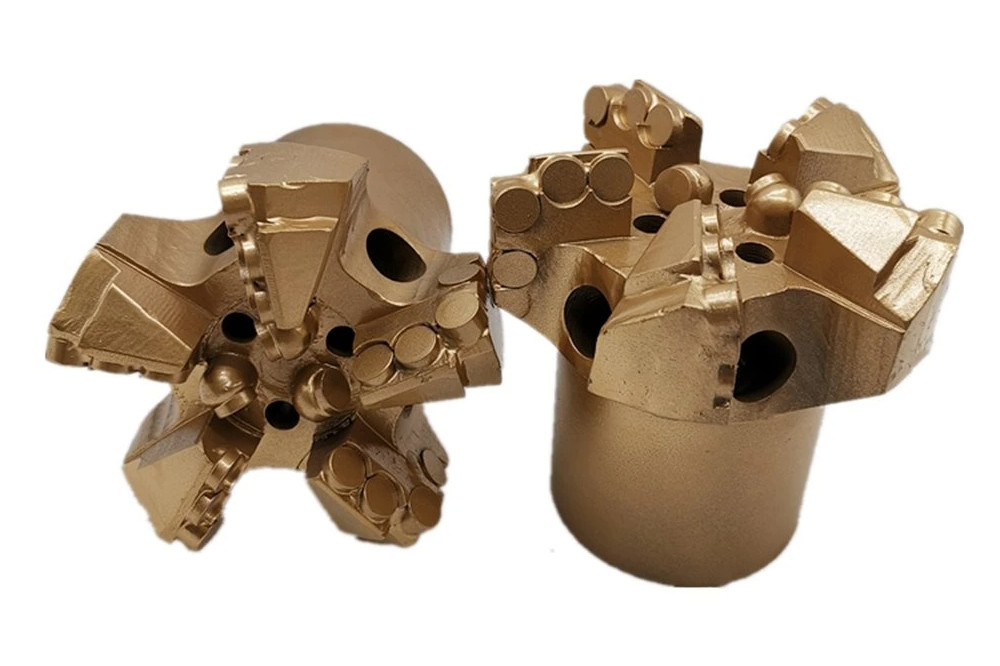

Izixhobo zokusika kunye nokuSila:

Izinto ezisisiseko kwiipleyiti ezihlanganisiweyo zedayimani zihlala zisetyenziselwa ukwenza izixhobo zokusika kunye nokusila ezifana namavili okugaya kunye neeblade.Iimpawu zesiseko semathiriyeli zinokuphembelela ukuqina kwesixhobo, ukuqina, kunye nokuguquguquka.

Izixhobo zokuNciphisa uBushushu:

I-Thermal conductivity ye-base material ibalulekile kwizixhobo zokutshatyalaliswa kobushushu.Iipleyiti zedayimani ezihlanganisiweyo zinokusebenza njengezinto ezisezantsi zokutshixa ubushushu obuphezulu bokuqhuba ngokufanelekileyo ubushushu.

Ukupakishwa kombane:

Izinto ezisisiseko kwiipleyiti zedayimani ezihlanganisiweyo zisetyenziselwa ukupakishwa kwezinto ze-elektroniki ezinamandla aphezulu ukunyusa ukusebenza kakuhle kokulahla ubushushu kunye nokukhusela izinto zombane.

Imifuniselo yoxinzelelo oluphezulu:

Kuvavanyo loxinzelelo oluphezulu, izinto ezisisiseko zinokuba yinxalenye yeeseli ezinoxinzelelo oluphezulu, ukulinganisa izinto eziphathekayo phantsi kweemeko eziphakamileyo zoxinzelelo.

Iimpawu

Iimpawu zezinto ezisisiseko kwiipleyiti ezidibeneyo zedayimani zichaphazela ngokuthe ngqo ukusebenza kunye nokusetyenziswa kwezixhobo.Nazi ezinye iimpawu ezinokuthi zibekho zemathiriyeli:

I-Thermal Conductivity:

I-thermal conductivity ye-base material ichaphazela amandla okuqhuba i-thermal yeplate edibeneyo yonke.I-conductivity ephezulu ye-thermal inceda ngokukhawuleza ukudlulisa ukushisa kwindawo engqongileyo.

Amandla oomatshini:

Izinto ezisisiseko kufuneka zibe namandla aneleyo omatshini ukuze kuqinisekiswe ukuzinza kunye nokuqina kweplate yonke edibeneyo ngexesha lokusika, ukugaya, kunye nezinye izicelo.

Nxiba Ukuxhathisa:

Izinto ezisisiseko kufuneka zibe nokuchasana okuthile kokumelana nokuxhatshazwa okuphezulu kunye neemeko zoxinzelelo ngexesha lokusika, ukugaya, kunye nemisebenzi efanayo.

Uzinzo kwiMichiza:

Izinto ezisisiseko kufuneka zihlale zizinzile kwiindawo ezahlukeneyo kwaye zixhathise ukubola kweekhemikhali ukuqinisekisa ukusebenza kwexesha elide.

Amandla okudibanisa:

Izinto ezisisiseko zifuna amandla okudibanisa okulungileyo kunye neekristale zedayimani ukuqinisekisa ukuzinza kunye nokuthembeka kweplate edibeneyo yonke.

Ukuziqhelanisa:

Ukusebenza kwezinto ezisisiseko kufuneka kuhambelane neempawu zeekristali zedayimani ukufezekisa ukusebenza kakuhle kwizicelo ezithile.

Nceda uqaphele ukuba kukho ubuninzi bezinto ezisisiseko kwiipleyiti ze-diamond composite, nganye ineempawu ezahlukeneyo kunye nokusetyenziswa.Ngoko ke, kwizicelo ezithile, izinto ezisisiseko ezifanelekileyo kufuneka zikhethwe ngokusekelwe kwiimfuno

Ulwazi Lwezinto eziphathekayo

| Amabanga | Uxinaniso(g/cm³)±0.1 | Ukuqina(HRA)±1.0 | I-Cabalt(KA/m)±0.5 | TRS (MPa) | Isicelo esicetyiswayo |

| KD603 | 13.95 | 85.5 | 4.5-6.0 | 2700 | Ifanele idayimani edityaniswe nepleyiti imathiriyeli esetyenziswa kwi geology, amalahle, kunye nokusetyenziswa okufanayo. |

| KD451 | 14.2 | 88.5 | 10.0-11.5 | 3000 | Ifanelekile kwi-diamond composite plate izixhobo ezisetyenziswa kwi-oilfield extraction. |

| K452 | 14.2 | 87.5 | 6.8-8.8 | 3000 | Ifanelekile kwi-PDC blade base base |

| KD352 | 14.42 | 87.8 | 7.0-9.0 | 3000 | Ifanelekile kwi-PDC blade base base. |

Ukucaciswa kweMveliso

| Uhlobo | Imilinganiselo | |||

| Ububanzi (mm) | Ubude (mm) | |||

| KY12650 | 12.6 | 5.0 | |

| KY13842 | 13.8 | 4.2 | ||

| KY14136 | 14.1 | 3.6 | ||

| KY14439 | 14.4 | 3.9 | ||

| YT145273 | 14.52 | 7.3 | |

| YT17812 | 17.8 | 12.0 | ||

| YT21519 | 21.5 | 19 | ||

| YT26014 | 26.0 | 14 | ||

| PT27250 | 27.2 | 5.0 | |

| PT35041 | 35.0 | 4.1 | ||

| PT50545 | 50.5 | 4.5 | ||

| Iyakwazi ukwenza ngokwezifiso ngokobukhulu kunye nemfuno yokwakheka | ||||

ngathi

I-Kimberly Carbide isebenzisa izixhobo zemizi-mveliso ephucukileyo, inkqubo yolawulo ephucukileyo, kunye nezakhono ezizodwa zokubonelela abathengi behlabathi kwibala lamalahle ngobuchule obuqinileyo betekhnoloji kunye nenkqubo ebanzi ye-VIK ye-Three-Dimensional.Iimveliso zithembeke kumgangatho kwaye zibonisa ukusebenza okuphezulu, zikhatshwa ngamandla amakhulu etekhnoloji angenawo oontanga.Inkampani iyakwazi ukuphuhlisa iimveliso ezisekelwe kwiimfuno zabathengi, kunye nokuphucula okuqhubekayo kunye nesikhokelo sobugcisa.